Everyone knows that to build great works, a foundation of bricks is indispensable. However, it is not clear where bricks come from and how they are produced. Therefore, if you have the opportunity to travel to Mekong Delta, especially the provinces of Vinh Long, Ben Tre,… you will encounter traditional ceramic brick making villages of people located along both sides of the river. And Vinh Long ceramic brick village, located next to romantic rivers is one of the most famous one in the region.

General information about Vinh Long Ceramic Brick Village

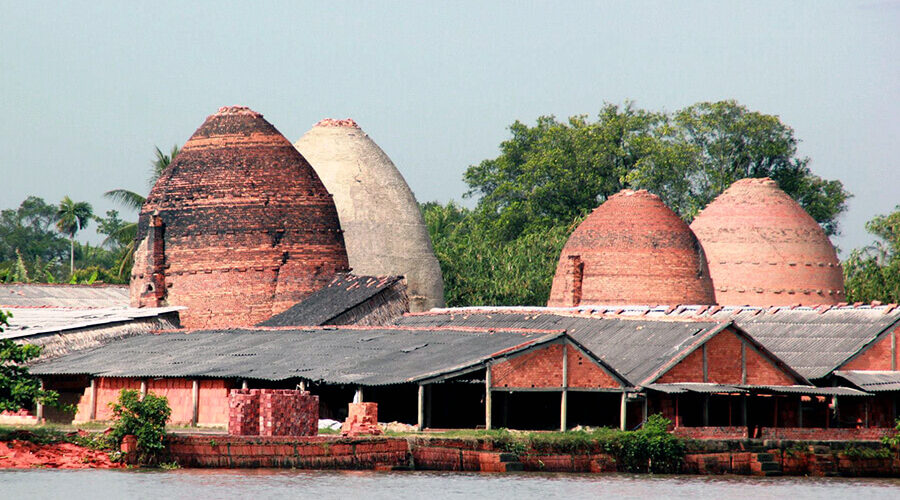

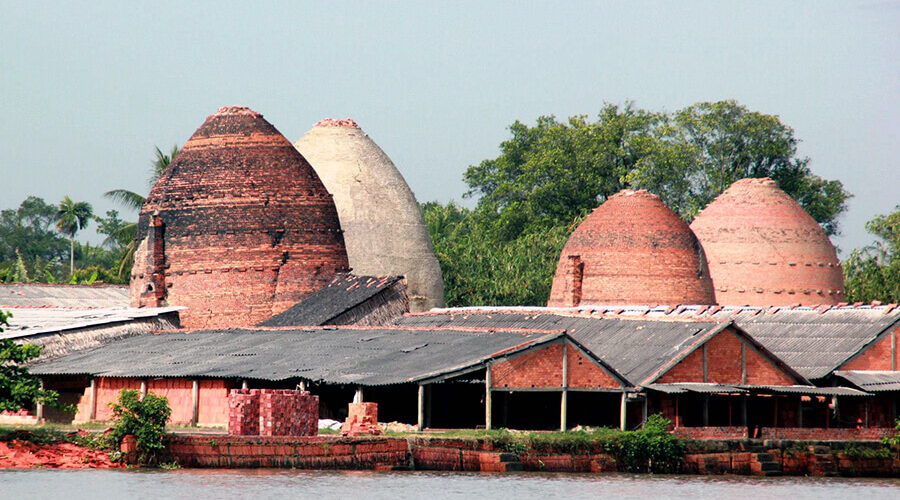

Among the brick and tile making villages in the Mekong Delta River, the area along the Co Chien River in Vinh Long province has the longest existence. The ceramic brick is located in Vinh Long province, stretching more than 30km, next to the poetic Co Chien river.

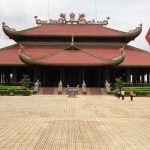

Vinh Long Pottery Village (source: collected)

The largest number of households participating in brick production is concentrated in Nhon Phu and My An communes, Mang Thit district, Vinh Long province.

What’s special about Vinh Long Ceramic Brick Village?

Separated from the main branch of the Mekong River, the two branches of Tien River and Hau River run throughout the South bringing millions of cubic meters of fertile alluvium to this vast delta. This volume of alluvium is not only a source of nutrients for rice fields or fruit gardens in four seasons, but also forms valuable primary clay mines.

This primeval clay mine is a great raw material to create products used in construction and decoration such as fired bricks, ceramics, etc. Through the talented hands of the craftsman, rough pieces of clay become useful products.

Source: collected

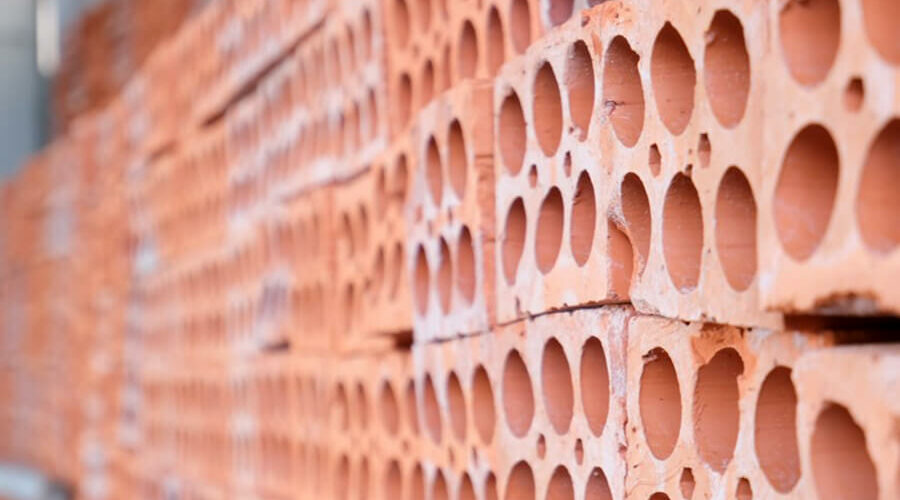

The quality of bricks in Vinh Long was so famous that traders from as far as Cambodia, Thailand, and Malaysia came to buy them and used them to build religious works with original red rustic bricks.

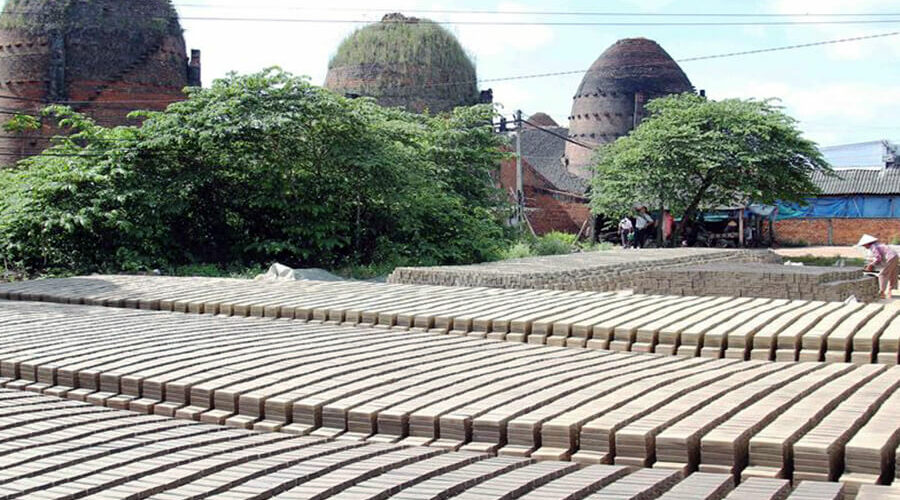

Coming to Mang Thit Brick Kiln, visitors not only have the opportunity to check-in and take photos but also learn about the brick making process. The raw clay is transferred from the boat to the workshop, then sorted and mixed with different techniques which decides the success of the batch. After mixing process, workers have to knead it many times until the clay turns smooth and non-stick to hands.

Source: collected

The next step is to pour the clay into the mold, which is different from the usual way of shaping by hand. After being removed from the mold, the raw product will be refined and polished with a wet sponge. This step makes the patterns and textures of the baked goods more detailed and sophisticated, increasing their value.

Source: collected

Useful information about Vinh Long Ceramic Brick Village

- Best for: solo, family, student.

- Entrance: Free

- Tourist spots nearby: Vinh Trang Pagoda, Thoi Son Islet, Vinh Long Ancient House Ecological Area, Vinh Long Museum, Vinh Sang Tourist Area, That Phu Temple (Ong Temple), Phu Ly Pagoda…

- Best way to visit Vinh Long Ceramic Brick Village: rent a private car with driver; book a Cai Rang Floating Market 1 day tour from HCMC.